Harvest campaigns 2016

Silage corn harvest September 2016

On the 27th of September 2016 the silage corn harvest was carried out on one of the SOILAssist test fields in Adenstedt.

The harvest involved the experimental tractor (New Holland T7.270), a New Holland corn chopper (FR550 Forage Cruiser) and a multi-purpose trailer with conveyor (Joskin Drakkar 7600). Furthermore, a self-propelled cleaner loader (Ropa Nawaro bunker mouse system Palandt) for overloading at the edge of the field was used by contractor J.-H. Deike and trucks for transport to the biogas plant. The subsequent mulching of the corn stubble was done with a tractor (New Holland M160), equipped with a front and side mounted mulcher (Agrimaster and Müthing).

During the silage corn harvest, the wheel crossing tests concentrated on determining soil pressure and deformation. A profile pit was required to set up the measuring point. The sensors were installed at three different depths using a mounting frame. Then the harvest chain crossed the prepared measuring point. To be able to examine the influence of the field traffic on the soil functions, soil samples was taken before the harvest in an unwheeled condition. The soil was then sampled after crossing of the entire machines of the harvest chain. The undisturbed soil samples were examined in the soil physical laboratory.

With the help of portable scales at the edge of the field, the exact weight of the machines used for harvest could be determined. In addition to other parameters such as tire inflation pressure or the number of wheel crossings, knowledge of the weight or wheel load is important for the experiments and for the evaluation of the influence of the various machines on the soil. The soil pressure and deformation measurements show us directly the effects of the current traffic on the soil. The investigations of the soil samples in the laboratory subsequently provide us with information on whether conductivity functions for water and air were influenced by field traffic and whether any damage occurred. This enables us to evaluate different mechanical loading situations when driving on arable land more effectively and to derive appropriate recommendations.

Sugar beet harvest October 2016

The sugar beet harvest in the SOILAssist project took place on the 24th of October 2016 in Adenstedt.

The self-propelled sugar beet harvester provided by machine cooperative Ambergau was a REXOR 630. It was a 6-row harvester with 3 axles and a bunker volume of 30 tons. It was adjusted by Grimme for the wheeling experiments of SOILAssist, e.g. by installing a measuring system for determining the bunker filling level and integrating corresponding software for recording the values and other machine data.

The experiments were carried out with full and half full bunker filling. The soil was sampled in the unwheeled condition before harvest and in the wheeled condition after harvest. In addition to soil sampling, infiltration experiments were also carried out. Since the sugar beets are stored in the headlands as a rent, the harvester repeatedly drives along the rent to empty the loader. This puts a heavy load on the soil in the headlands (high wheel load combined with high wheel crossing frequency). To investigate these effects, soil samples were also taken in the headlands before and after harvesting.

To determine the wheel loads of the sugar beet harvester with full and half-full bunker for the wheel crossing experiments, portable scales were used at the edge of the field and the loads for each wheel were determined axle by axle. The wheel contact area was also measured, which is another important parameter in addition to the tire inflation pressure and wheel load. For this purpose, the tires of the three axles had to be marked and sprayed from all sides with chalk powder. The resulting tire imprint could then be drawn on a plastic foil. The complete contact area of the tire including the lug contact area is thereby determined.

The investigation of soil pressure and soil deformation as well as undisturbed soil samples in combination with the recording of the respective traffic situation and the corresponding position on the field (RTK-GPS) also permits a spatial allocation of soil loads and load hot spots during harvesting. In addition, the observation of a field over several years allows statements to be made about the soil loads of an entire crop rotation or different crop sequences. Therefore, in SOILAssist we work on several fields at the same time to be able to examine each crop in each year on the one hand and to map the entire crop rotation of a field on the other hand as well as to measure the accumulation of the loads over time.

SOILAssist project meeting in Adenstedt in September 2016

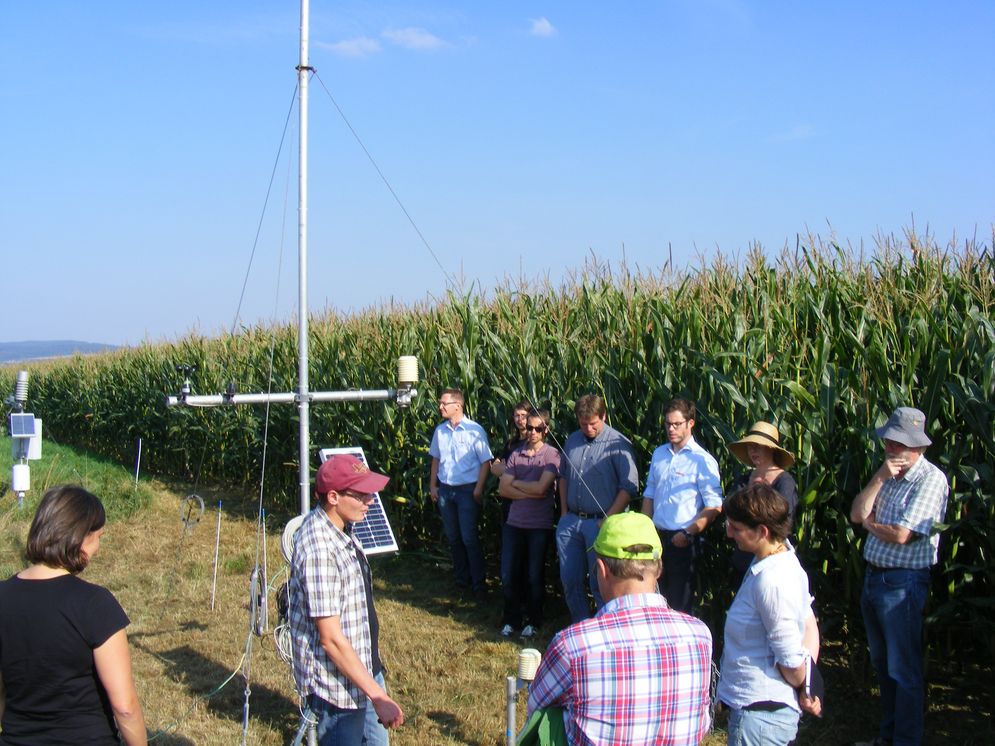

From 8th to 9th of September the SOILAssist project team, representatives of the BonaRes Centre and the project management Jülich as well as company representatives of Grimme came together. The meeting took place at the test site in Adenstedt. In addition to the lectures and discussions, a visit to the study fields was also part of the program. The participants presented their work in the project and exchanged information about the current status and future tasks.

On the first day, the project partners gave an overview of the on-board assistance system, the sensor system and the planning system as well as in spatial modelling. A live demo of a prototype of the planning system with Graphical User Interface was demonstrated. In the afternoon a visit of study fields of the project was on the agenda. Thereby the weather station especially built for the project was presented and the functionality of the individual devices was explained. The soil conditions of the test site were elucidated with the help of a soil profile pit and a soil profile characterization was performed. During a field demonstration of the functionality of a subsoiler, the advantages and disadvantages of subsoiling regarding soil compaction processes were discussed. This also included the excavation of a small pit on which the simple soil structure assessment for the farmer was introduced. On a New Holland test tractor, a first version of the sensor system in the tire and its integration into the on-board assistance system could be presented on a tablet in the tractor cabin.

On the second day the project partners presented the socio-economic evaluation of the project as well as the acceptance and implementation of soil protection measures. Furthermore, the representatives of the BonaRes Centre presented their main tasks of cross-project coordination. In addition, models and tools will be developed that describe the influence of land use measures on the soil system. Furthermore, the data center, which comprises data management and the consolidation of data from soil research into a central database for soil sciences, as well as a portal as a web-based interface for knowledge, information and services, are part of their work. In addition to the subsequent discussion of the upcoming field trials this year, the final discussion on the core questions and topics of the project provided important suggestions for the project team.

BonaRes status seminar Leipzig

On the 14th and 15th of November 2016, the status seminar of the BMBF funding initiative "soils as a sustainable resource for the bioeconomy" took place in Leipzig. The SOILAssist team was involved along with nine other project networks and presented the project and its initial results.

[Translate to English:] Plant 2030/BonaRes Statusseminar Potsdam

From the 14th to the 16th of March 2016 the PLANT 2030 Status Seminar took place in Potsdam. SOILAssist participated as a project of the BMBF's funding program. In addition to a poster presentation, the SOILAssist team presented its project.